APPLICATIONS

BE265 can be used for the following applications:

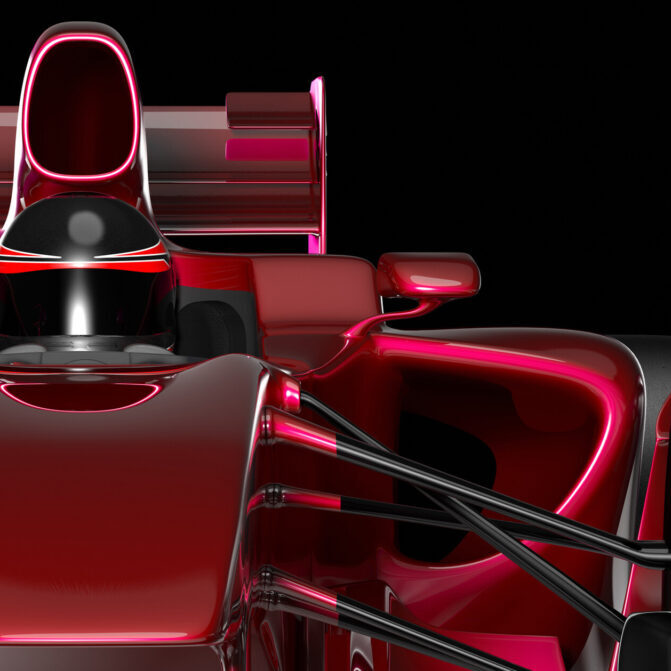

- Automotive modelling

- Direct-to-part manufacturing

FEATURES & BENEFITS

BE265 is a high-performance material designed to meet the demands of extreme-temperature applications.

- Excellent surface finish

- Low coefficient of thermal expansion

for consistent, reliable performance - Good dimensional stability

- Excellent temperature resistance

- Easy to machine

- Inert surface

WANT TO FIND OUT IF THIS PRODUCT IS RIGHT FOR YOU?

Board Sizes

BE265 is a made-to-order material with a minimum order quantity of 6m³

Board sizes available include (length x width +/- 1mm x depth +/- 0.5mm)

1524mm x 608mm x 50mm

1524mm x 608mm x 75mm

1524mm x 608mm x 100mm

ANCILLARY MATERIALS

BE265 is available with compatible adhesives, repair pastes, sealers and release agents. Find out more about our compatible products here.

For blocking up, back up or framing structures, use a matched adhesive. Variations in the coefficients of thermal expansion (CTE) of boards, adhesives and back up or framing materials may introduce stress into composite structures when they are heated or cooled.

Use caution with variations in CTE as this may cause warping or micro-cracking when subjected to heat.